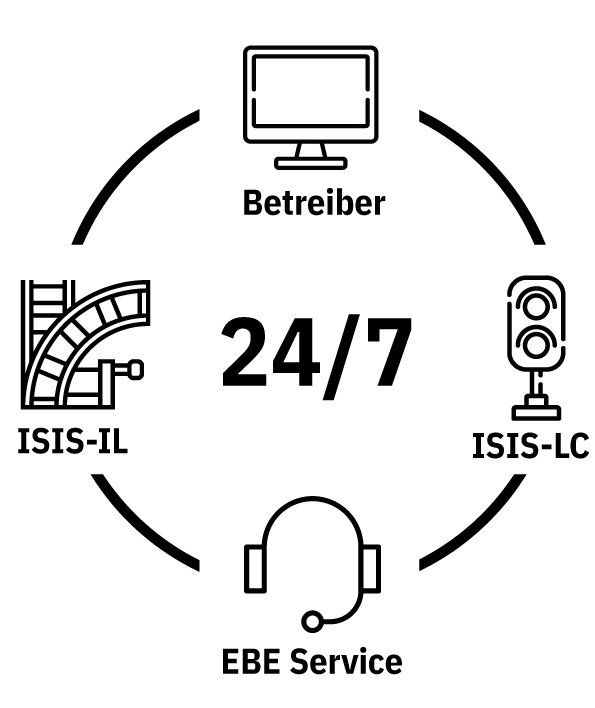

Only at EBE: communicating components

– you always have your systems on screen

The ISIS-LC safety systems for level crossings, our ISIS-IL interlocking solutions, the EBE ISMO control centre and our customers are in constant communication with each other. You always have the status of all systems on screen, just as we do as service partners. Read more about the ISIS-IL interlocking solutions in the second issue of our Level X magazine.

ISIS-LC: Flexible and efficient solutions

for the protection of level crossings

Our ISIS-LC systems (innovative system for intelligent safety at level crossings) are future-oriented level crossing safeguarding systems, based on commercially available components (complete interior system), supplemented by field elements (light signal heads, barrier drives, track switching equipment) specially developed for railway applications. The flexible technical platform was developed in accordance with the CENELEC standards EN50126/EN50128 and EN50129 and has approvals according to CENELEC up to and including SIL4.

The use of state-of-the-art and proven industrial and railway technology components ensures high reliability and long-term availability of the components. The centrally and decentrally expandable safety-related control system as the core of the system enables a previously unknown flexibility and thus the customer-specific adaptation of the system without costly new approvals.

ISIS-LC is designed to reduce both the investment costs and the life-cycle costs of level crossing / railway crossing safety systems in the long term. For this reason, ISIS-LC is designed to be low-maintenance and enables components to be replaced quickly and easily.

The core element is the main controller - a safety-oriented programmable logic controller (PLC) supplied by the Pilz companys and configured with two or multiple channels in accordance with the given safety level. The main controller assumes all control and monitoring tasks. The conditions for controlling and monitoring the light signals and barriers, the dependencies for activating the driver indication signals, the monitoring the voltage supply and the manual control logic and evaluating the axle counters are key functions which have been implemented as part of the software in the main controller.

The signalisation is initiated by ISIS-LC using low-power LED signals. These feature an integrated monitoring system where the light source and the monitoring have been configured using two channels. Durable and low-maintenance motors are used for the electromechanical barrier drives. The control and regulation of the opening and closing times, as well as the monitoring of the barrier position, is realised via the main controller and the motor control circuits integrated into the barrier drive. The monitoring of the barrier position is realised via redundantly operating sensors which signal the position of the barrier to the main controller.

Wheel sensors for counting axles in combination with specially implemented algorithms in the central computer ensures the safe and reliable recording of train movements and subsequently the activation and deactivation of the safety system.

ISIS-LC is equipped with safety-oriented IP-based protocols, as well as parallel interfaces in order to ensure the simple connection of the level crossing safety system to the other systems (i.e. the interlocking systems, etc.). The other safety systems can either be connected directly to the level crossing or via a remote monitoring controller. This is also configured as a safety-oriented PLC and communicates with the main controller for one or several level crossings.

Furthermore, the system registers all occurences, errors and faults and provides extensive array of diagnostic functions via an installed Panel PC with a user-friendly touch screen.

Optional off-grid power supply, © EBE Solutions

Optional off-grid power supply, © EBE SolutionsProtected against failure and overvoltage

All the system components are designed for extended temperature ranges and allow the installation of the control components in outdoor cabinets. A proven lightning protection concept reliably safeguards all the components against the influences of overvoltages.

Both the SIL4 and SIL2 architectures reliably handle all the individual faults, whereby the EN50129 fail-safe principles have also been universally applied.

The low energy consumption not only reduces the running costs of the system, but also enables the grid-autonomous supply of a level crossing with solar panels and buffer batteries in special design variants.

The advantages at a glance

- Developed according to EN50126, EN50128, EN50129

- SIL4-certified

- Adaptable safety architecture (SIL2 and SIL4 versions with the same components)

- Low energy consumption

- Flexible system concept

- Extensive diagnostics

- Low investment and life-cycle costs

- Variants with solar power supply available